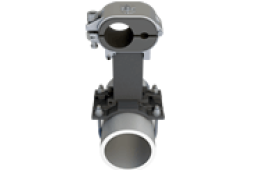

MUX Clamps

ABCO Subsea has sold more than 20,000 MUX clamps over the past 15 years, and these clamps are now in use on more than 75 drilling rigs around the world. The MUX clamp is used for clamping electrical, fiber-optic or monitoring cables to marine drilling risers.

MUX clamps are custom engineered to hold up to four lines and can be mounted inside or outside syntactic foam.

ABCO Subsea’s MUX clamps have shells built from 316-L stainless steel and the clamp’s inserts are made of nitrile butadiene rubber. The rubber inserts are replaceable for conversion due to umbilical changes.

The clamps all have a low profile to eliminate any unwanted drag on the parts. A 1/2″ socket is formed into the shaft to speed installation and ensure proper torquing of the clamp. The clamps can be secured to the base with a removable pin. The pin is attached to the housing with a stainless steel lanyard so that no loose parts are ever exposed over the water.

ABCO Subsea also offers SB Clamps and custom clamps.

For more information please contact us or fill out our MUX Clamp Product Inquiry.

ABCO Subsea MUX Clamp Pull Test

MUX Clamp Technical Data

| 2″ HSDW Clamp | 3″ HSDW Clamp | Double Decker HSDW Clamp | |

|---|---|---|---|

| Weight in Air: | 10 lbs. (4.5 kg) | 12.6 lbs. (5.7 kg) | 13.57 lbs. (6.2 kg) |

| Weight in Water: | 7.7 lbs. (3.5 kg) | 8.9 lbs. (4.0 kg) | 9.91 lbs. (4.5 kg) |

| Length: | 7.05” (179.1 mm) | 8.3” (210.8 mm) | 7.95“ (201.9 mm) |

| Width: | 5.3” (134.6 mm) | 5.3” (134.6 mm) | 5.3“ (134.6 mm) |

| Height: | 4.6” (116.8 mm) | 5.4” (137.2 mm) | 6.4” (162.6 mm) |

| Pipe Size Range: | 4“ OD to 6.75” OD | 4“ OD to 6.75” OD | 4“ OD to 6.75” OD |

| # of Lines per Clamp: | 1 or 2 | 1, 2, or 3 | up to 4 |

| Max Line OD: | 2.0“ (50.8 mm) | 3.0” (76.2 mm) | 2” (50.8 mm) |

Material Specs:

| CLAMP SHELL AND MOUNTING BRACKETS | |

|---|---|

| Material Designation | 316 – L Stainless Steel |

| Manufacturing Process | Lost Wax Investment Casting |

| Tensile | 81,000 psi |

| Yield | 42,000 psi |

| Elongation | 50% |

| FASTENERS | |

|---|---|

| Material Designation | 316 – L Stainless Steel |

| Manufacturing Process | Cold Formed |

| Tensile | 85,000 psi |

| Yield | 45,000 psi |

| Elongation | 50% |

| RUBBER INSERTS | |

|---|---|

| Material Designation | Nitrile Butadiene Rubber |

| Manufacturing Process | Injection Molded |

| Elongation at break | 440% |